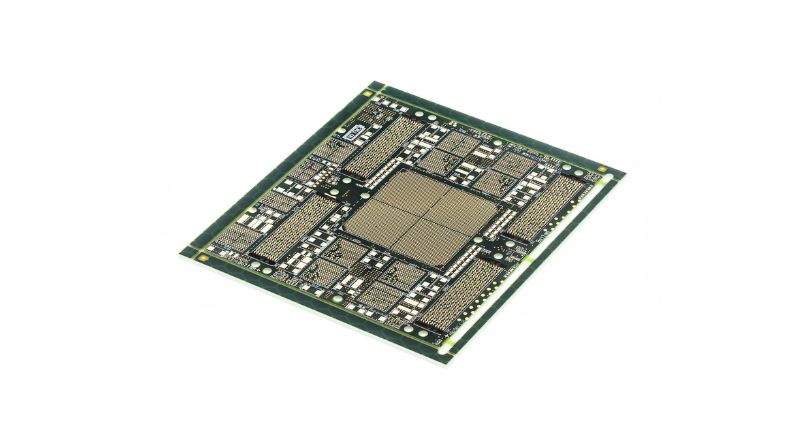

The construction of a PCB is what determines how the board will behave. There are two primary methods of PCB construction, called “single-sided” and “double-sided”. Single-sided boards can be made using one of two techniques; FR-4 or PCB crore.

FR-4 boards are built using epoxy resin and fiberglass as the base materials. These components are laminated together under high pressures and temperatures to form the base material for the circuit board. FR-4 has a low thermal expansion rate which means that it won’t change size very much when heated or cooled, making it ideal for certain types of applications where thermal expansion can cause problems

The construction of a PCB is what determines how the board will behave.

The construction of a PCB is what determines how the board will behave. There are two primary methods of PCB construction, called “single-sided” and “double-sided”. Single-sided boards have a ground plane on one side only. The other side is covered by copper, but it does not serve as an electrical connection. Double-sided boards have copper on both sides and act as part of their ground plane.

There are two primary methods of PCB construction, called “single sided” and “double sided”.

PCBs can be manufactured using single sided and double sided construction. There are two primary methods of PCB construction, called “single sided” and “double sided”.

Single sided boards are made using one of two techniques; FR-4 or pcb crore. FR-4 is a glass epoxy laminate material that has been developed specifically for use in printed circuit boards. This material has an insulating layer on both sides of it which protects the copper traces from being damaged by electrostatic discharge (ESD). When we say “FR-4”, this refers to what kind of epoxy resin was used to make the board – there are many different combinations available in order to achieve certain properties such as moisture resistance or thermal expansion control etc.,

but all FR-4 based boards will be made using a similar method regardless of their individual characteristics. The other technique used for high volume production is called pcb crore, which stands for pressure sensitive conductive film – this process involves applying conductive ink onto one side only before exposing it all together once again through a negative masking process that creates positive patterning within each dielectric layer so as not disturb any traces already drawn on them during previous steps within its manufacturing process.[1]

Single sided boards can be made using one of two techniques; FR-4 or pcb crore.

One of the most significant advantages of using FR-4 is its ability to be made in a single sided design. This means that it doesn’t need an additional layer of copper foil, which is what makes PCB crore boards so incredibly lightweight and easy to work with.

FR-4 boards are built using an epoxy resin, fiberglass as the base materials. These components are laminated together under high pressures and temperatures to form the base material for the circuit board. The finished product has excellent thermal properties and strong mechanical strength which make it ideal for use in many different applications

FR-4 boards are built using an epoxy resin and fiberglass as the base materials.

FR-4 boards are built using an epoxy resin and fiberglass as the base materials. The glass fibers provide strength to the board, while the epoxy provides a high dielectric constant, which gives it its insulating properties PCB crore vs foil construction.

The FR-4 board has become very popular in circuit board manufacturing because of its many advantages over other materials:

- FR-4 is more durable than other plastics and can withstand higher temperatures than most PCBs. It’s also more resistant to chemicals and corrosion than other plastics such as acrylic or polyester.*

- FR-4 has good thermal conduction properties because it conducts heat well over long distances.*

These components are laminated together under high pressures and temperatures to form the base material for the circuit board.

FR-4 is a laminate material. FR-4 is made from a combination of glass and epoxy. It can be used for many different applications, including printed circuit boards (PCBs).

FR-4 has a low thermal expansion rate which means that it won’t change size very much when heated or cooled, making it ideal for certain types of applications where thermal expansion can cause problems.

FR-4 has a low thermal expansion rate which means that it won’t change size very much when heated or cooled, making it ideal for certain types of applications where thermal expansion can cause problems.

FR-4 is a good choice for high-temperature applications. Many electronic components have an operating temperature range (e.g., -40 to 85°C). FR-4 has higher mechanical strength than glass epoxy and can withstand these high temperatures without breaking down the way the other materials do.

The construction process matters more than you might realize!

When you think about the construction of your circuit board, what comes to mind? Maybe you think it’s just a bunch of components arranged on a layer of copper foil and then covered with another layer of epoxy resin. But this process is more complex than it may seem at first glance. The choice between PCB, hybrid and flexible circuits can affect more than just the cost of building your circuit boards; it will also have an impact on quality, performance and environmental impact.

Consider these factors before choosing which type of circuit board is best for your next project:

Conclusion

As you can see, there are many different ways to build a PCB. The choice of construction method is dependent on what type of application you’re building and what your needs are as a designer. If you’re unsure which method would best suit your needs, then we recommend getting in touch with one or more of our engineers so they can help guide you towards the right answer!