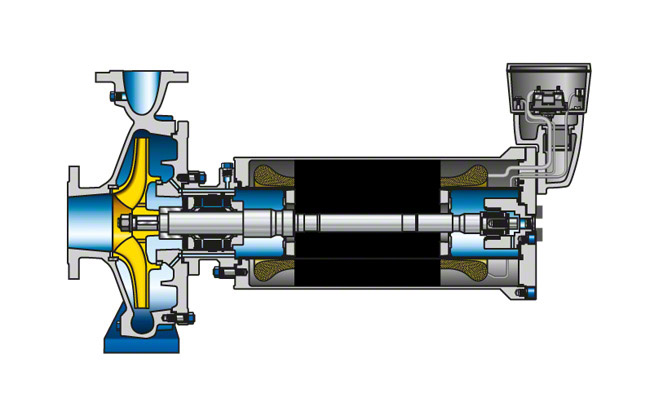

Pump users have long been familiar with the traditional centrifugal and positive displacement pumps, but with the advent of canned motor pumps, there has been a growing interest in this newer type of pump.

- Compact design

- High efficiency

- Ability to handle challenging liquids

- Environments

One of the main benefits of canned motor pumps is their compact design. Unlike traditional pumps, canned motor pumps do not require a separate motor and pump housing. Instead, the motor and pump are integrated into a single unit, which reduces the overall size and weight of the pump. This makes canned motor pumps ideal for applications where space is limited, such as in small processing plants or on offshore platforms.

Advantages of canned motor pumps

Another advantage of canned motor pumps is their high efficiency. Traditional pumps often rely on mechanical seals to prevent leakage, but these seals can be a source of energy loss. Canned motor pumps, on the other hand, use magnetic coupling to transmit power from the motor to the pump. This eliminates the need for mechanical seals and reduces energy loss, resulting in higher efficiency.

Canned motor pumps are also known for their ability to handle challenging liquids and environments. These pumps can handle liquids that are abrasive, corrosive or have high viscosity. They are also well-suited for high-temperature or high-pressure applications. This makes canned motor pumps ideal for a wide range of industries, including chemical, petrochemical, and oil and gas.

However, canned motor pumps are not without their drawbacks. One of the main concerns among pump users is the cost. Canned motor pumps can be more expensive than traditional pumps, which can be a significant barrier for some users. Additionally, canned motor pumps are more complex than traditional pumps, which can make them more difficult to repair and maintain.

Despite these drawbacks

Many pump users are still drawn to canned motor pumps for their benefit. The compact design and high efficiency of canned motor pumps make them ideal for a wide range of applications. Additionally, the ability to handle challenging liquids and environments makes them well-suited for a wide range of industries.

Another concern among pump users is the availability of spare parts. Canned motor pumps are more complex than traditional pumps, which can make it more difficult to find replacement parts. Additionally, canned motor pumps often require specialized training and knowledge to repair and maintain, which can be a barrier for some users.

Despite these concerns, many pump users are still drawn to canned motor pumps for their benefits. The compact design and high efficiency of canned motor pumps make them ideal for a wide range of applications. Additionally, the ability to handle challenging liquids and environments makes them well-suited for a wide range of industries.

In conclusion

Fnengg manufactures Canned motor pumps that have been gaining popularity among pump users for their compact design, high efficiency, and ability to handle challenging liquids and environments. While canned motor pumps can be more expensive and complex than traditional pumps, many users are willing to pay the price for the benefits that canned motor pumps offer. As technology continues to improve, canned motor pumps will likely become even more popular among pump users.